Learn about Motorcycle Repair & Maintenance

Introduction: Why Maintenance Matters (and What You’ll Learn)

Motorcycle maintenance is more than a chore; it is a habit that turns miles into memories and risk into reliability. Keeping components clean, adjusted, and within specification directly influences safety, performance, and cost of ownership. Tire pressure alone can shape handling and braking distance, while fresh brake fluid resists fade on steep descents. A well-lubricated chain reduces friction losses and protects sprockets from premature wear. And beyond the mechanical gains, there is the calm confidence that comes from knowing how each system on your machine works and how to keep it in top shape.

Reliability is built from small routines. Engine oil carries away heat and contaminants, but it degrades with time, heat cycles, and fuel dilution. Coolant prevents corrosion and stabilizes temperature but slowly loses inhibitors. Brake fluid is hygroscopic, absorbing moisture that lowers boiling point; many manufacturers recommend replacement every two years. Battery health can be inferred from voltage readings: around 12.6 V at rest indicates a full charge, while a charging system typically sits near 13.5 to 14.5 V at cruising rpm. These are typical figures, and your service manual is the primary authority for exact intervals and specifications.

Here is the outline of this guide and how to use it. Skim the section summaries now, then return to each when it is time to work on that system.

– Section 1: Big-picture value, safety context, and how to approach maintenance with a plan.

– Section 2: Setting up your workshop, essential tools, and safe techniques that prevent damage.

– Section 3: Routine care for fluids, filters, drive systems, tires, and electrical items with practical intervals.

– Section 4: Troubleshooting logic for no-starts, rough running, odd noises, and brake or suspension quirks.

– Section 5: A conclusion that converts lessons into a seasonal and long-term ownership roadmap.

Think of this article as a long, smooth corner: set up properly, look through the exit, and commit. Each section provides arguments, examples, and data where helpful, and all recommendations defer to the official service manual for torque values, clearances, and model-specific steps. With consistent practice, a maintenance day can feel like meditation, the satisfying click of a torque wrench punctuating the afternoon.

Workshop Setup, Tools, and Safety: Building a Solid Foundation

A tidy workspace and the right tools turn frustrating jobs into predictable, repeatable tasks. Start with level ground and stable support; a center stand or quality paddock stands keep the motorcycle upright and reduce the chance of tip-overs. Good ventilation matters, especially when draining fuel or running the engine briefly for diagnostics. Keep a fire extinguisher nearby, store chemicals in labeled containers, and dispose of used fluids according to local rules. Lay out clean rags, a parts tray, and zip-top bags so fasteners can be grouped and labeled by step.

Essential tools include a torque wrench that covers the fasteners you use most; many common chassis bolts sit in the 10 to 60 N·m range, while small cover screws are far lower. Use hex and Torx keys that fit cleanly to avoid rounding. A quality tire pressure gauge, chain alignment tool, and a multimeter multiply your accuracy. Medium-strength threadlocker helps prevent loosening on vibration-prone hardware, while anti-seize on high-heat joints (where specified) eases future disassembly. Always confirm where thread treatments are appropriate; some fasteners require dry threads and exact torque values.

– Baseline kit: socket set with extensions, combination wrenches, hex/Torx keys, screwdrivers, needle-nose pliers, side cutters, feeler gauges, tire gauge, chain breaker/riveter (for chain-drive models), torque wrench.

– Support and safety: stands, wheel chocks, nitrile gloves, eye protection, shop towels, spill pads, funnels, drain pans.

– Measurement and testing: digital multimeter, calipers for rotor and pad checks, spark tester, compression and leak-down tools if you plan deeper diagnostics.

Safe habits protect you and the machine. Disconnect the negative battery terminal when working on live circuits. Keep fingers away from the chain while the engine runs; align and tension with the engine off. Let the engine cool before opening the radiator cap; hot systems are under pressure. When torquing fasteners, hold the wrench at the handle and pull steadily until the click; do not “double click.” When lifting the motorcycle, double-check stand engagement and clear the area so a stumble does not become a fall. Finally, establish a rhythm: read the manual, prepare the tools, perform the task, verify, then log the work. That simple loop reduces mistakes and builds mechanical intuition.

Routine Care: Fluids, Filters, Drive Systems, and Tires

Routine maintenance pays dividends through better feel, efficiency, and longevity. Engine oil and filter changes are the heartbeat of this routine. Many engines thrive on changes in the range of 3,000 to 6,000 miles or annually, with shorter intervals for high-heat city riding and longer for light-duty cruising; always defer to the service schedule for your machine. Watch for fuel smell, metal particles, or milky emulsions during changes, as these hint at dilution, wear, or coolant contamination. Use the correct viscosity and specification noted in the manual, and replace the crush washer to prevent leaks.

Coolant prevents freeze damage, corrosion, and overheating. Replace coolant every 2 to 4 years depending on type and service; inspect hoses for bulges, cracks, or weeping at clamps. Brake fluid, typically DOT 3, 4, or 5.1 in many motorcycles, should be renewed about every two years because moisture lowers boiling point and can corrode internal parts; never mix incompatible fluids and avoid silicone-based types unless specifically specified by your model. Check pads through the caliper window and measure remaining material; replacing around the 1 to 2 mm mark is common practice, but follow the service limit. Inspect rotors for grooves and measure thickness against the minimum stamped on the carrier.

Drive systems require focused attention. Chain-drive motorcycles often call for 25 to 35 mm of free slack measured at the midpoint between sprockets; measure per the manual, since slack changes with suspension position. Clean with a gentle solvent or designated chain cleaner, then lube the rollers after a ride while the chain is warm. A belt drive looks low maintenance, but it still needs periodic tension and condition checks; watch for missing teeth or frayed edges. Shaft-drives trade adjustments for periodic final-drive oil changes; renew the gear oil at the interval listed, and inspect seals for seepage.

Tires are the only contact with the road, and small changes matter. Pressure can drift with temperature and time; check cold pressures at least weekly and before longer trips. Underinflation builds heat and dulls steering; overinflation reduces the contact patch and can increase stopping distances on bumpy surfaces. Inspect tread for even wear and embedded objects, and look at the sidewalls for cracks. Tire age matters; many riders replace around the 5 to 6 year mark even with remaining tread because rubber stiffens and grip declines. Spin wheels to feel for bearing roughness, and confirm that valve stems are supple and caps installed. Finally, give the battery a moment of attention: clean terminals, ensure a solid ground, and measure voltage after resting overnight; around 12.6 V suggests a healthy charge, while significantly lower numbers hint at a failing cell or parasitic draw.

– Quick weekly checklist: tire pressures, lights and horn, chain slack and lube, brake pad glance, oil level sight glass, coolant in overflow tank, and a short test of the brake lever and pedal for a firm feel.

Troubleshooting: From No-Start to Odd Noises

A logical flow saves hours when a motorcycle misbehaves. Start with the symptom, then rule out simple causes before chasing exotic faults. For a no-start, confirm the basics: sufficient fuel, run switch on, neutral selected or clutch pulled, and side-stand interlock behaving as intended. Listen when pressing the starter; a single click suggests a weak battery or poor connection, a rapid chatter can indicate low voltage, and silence may point to a switch or relay. Measure battery voltage at rest and while cranking; a healthy battery often reads about 12.6 V at rest and should not sag far below roughly 10 V while cranking. Clean and tighten both battery terminals before moving deeper.

If the engine cranks but will not fire, think spark, fuel, air, and compression. Use a spark tester to verify consistent spark. If spark is present, crack the drain on a carburetor bowl (if equipped) to confirm fuel delivery, or listen for the fuel pump prime on key-on for fuel-injected systems. A clogged air filter can choke the engine; hold the filter up to light and replace if it is dark and packed. For persistent issues, a compression test can highlight worn rings or valves. Many healthy engines show well over 120 psi, but absolute numbers vary; compare cylinders to each other and verify against the manual. A leak-down test gives even more clarity, allowing you to hear whether air escapes through intake, exhaust, or crankcase pathways.

Rough running and hesitation often trace back to vacuum leaks, aging plugs, or stale fuel. Replace spark plugs at the recommended interval, and inspect plug color for clues: oily, sooty, or blistered insulators each tell a story. Check for cracked intake boots or loose clamps, as small leaks lean out mixtures. For fuel injection, ensure connectors are seated and grounds are clean. Some modern motorcycles expose basic diagnostic codes through a standardized connector; a simple reader can point you toward a faulty sensor, though many models rely on manufacturer-specific procedures that are outside general tools.

Odd noises deserve a patient ear. Chain slap can sound like a rhythmic rattle at low speed; adjust slack and confirm alignment. A dry clutch or low oil can create chatter or whine; verify level and condition. Wheel bearings growl when leaned; with the bike on a stand, spin the wheel and feel for roughness. A soft brake lever often indicates air in the system; bleeding restores firmness and removes moisture. Steering head bearings that have notched can cause a center detent; raise the front and swing the bars to feel for smooth movement. The key is to change one variable at a time, record the result, and avoid shotgun part replacement. A notebook and a slow heartbeat are often the most effective tools in the box.

– Troubleshooting ladder: verify power, verify spark, verify fuel, verify air, verify compression, and inspect mechanical timing before assuming complex electronic faults.

Conclusion and Ownership Roadmap: Keep the Momentum

Effective motorcycle maintenance blends curiosity with discipline. Set realistic intervals based on your manual, your riding conditions, and your calendar. City commutes with frequent heat cycles and short trips often justify shorter oil intervals; long, steady rides may allow longer gaps within the specified range. Tire checks every week become a two-minute ritual that pays back every time you brake or swerve. Brake fluid every two years and coolant on its schedule protect systems you cannot easily see. Valve inspections, where applicable, keep top-end parts happy; treat them as investments in smooth miles.

Build a simple log. Record date, mileage, task, and parts used. Photographs of hose routes and cable paths help during reassembly. Group small tasks into a quarterly session so you spend more time riding and less time setting up. If a job overwhelms you, consider a hybrid approach: you handle the inspections, cleaning, and bolt checks; a qualified technician tackles tasks that demand special tools or deep experience. That division keeps costs predictable while preserving your hands-on connection to the machine.

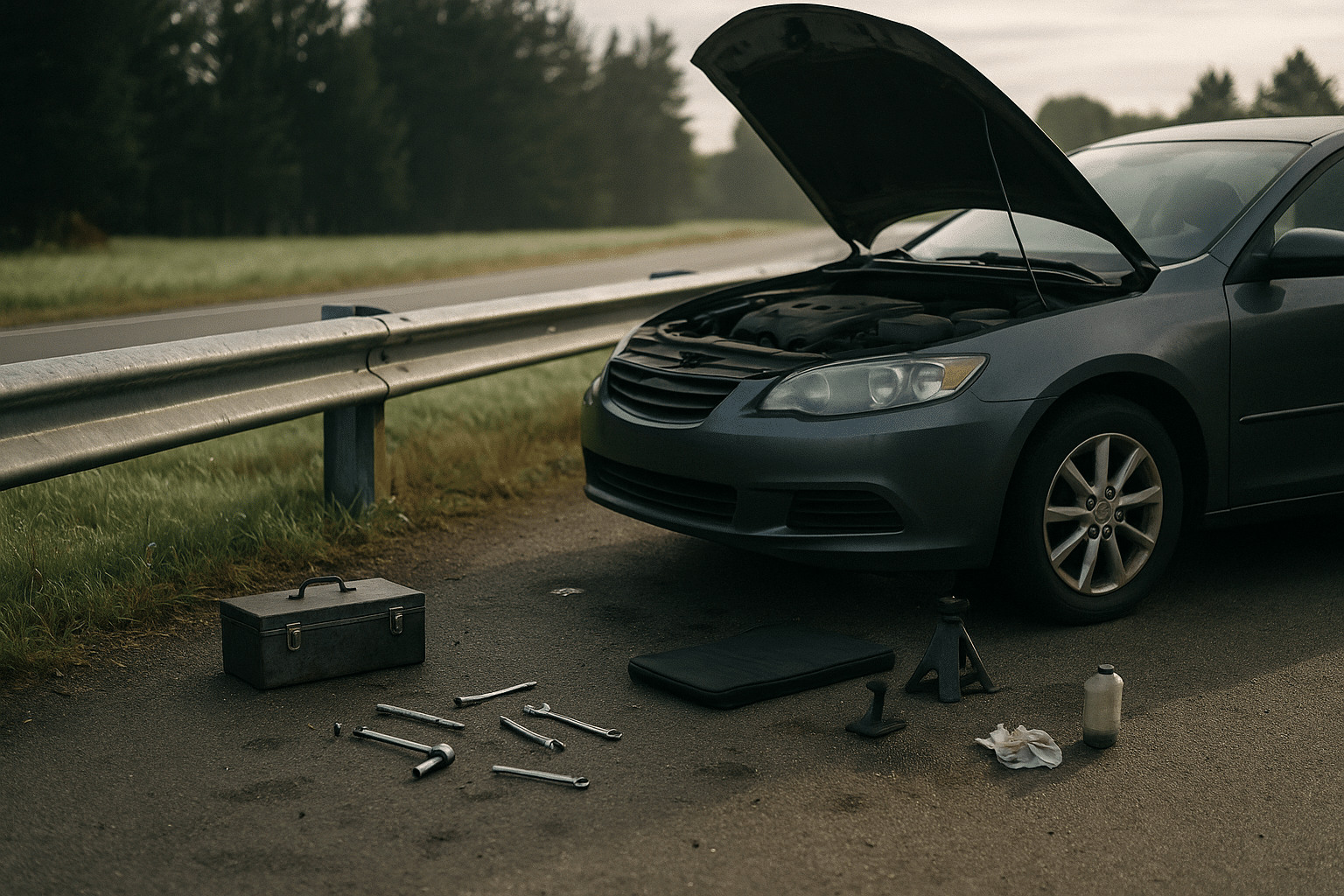

Seasonal habits matter too. Before storage, change oil, fill the tank and treat fuel, connect a maintenance charger, and raise tire pressures slightly to combat flat-spotting. During riding season, wash gently and re-lube the chain after wet rides, then run a fastener check on items that experience vibration. A pre-ride sweep takes minutes: lights, horn, brake feel, tire pressures, chain slack, and a walk-around for leaks. Those small steps guard against the kind of preventable roadside delays that sour a day.

– Your roadmap: weekly tire and control check, monthly chain service and fastener glance, quarterly thorough inspection, annual fluids, and multi-year coolant and valve tasks according to the manual.

Motorcycle ownership rewards the rider who listens. Listen to the hum of a healthy engine, the click of a properly torqued bolt, and the silence that follows a job done right. Keep tools clean, respect specifications, and write things down. In return, the machine will meet you at the edge of town ready to explore, not complain. That is the quiet promise of routine repair and maintenance, and it is well within your reach.